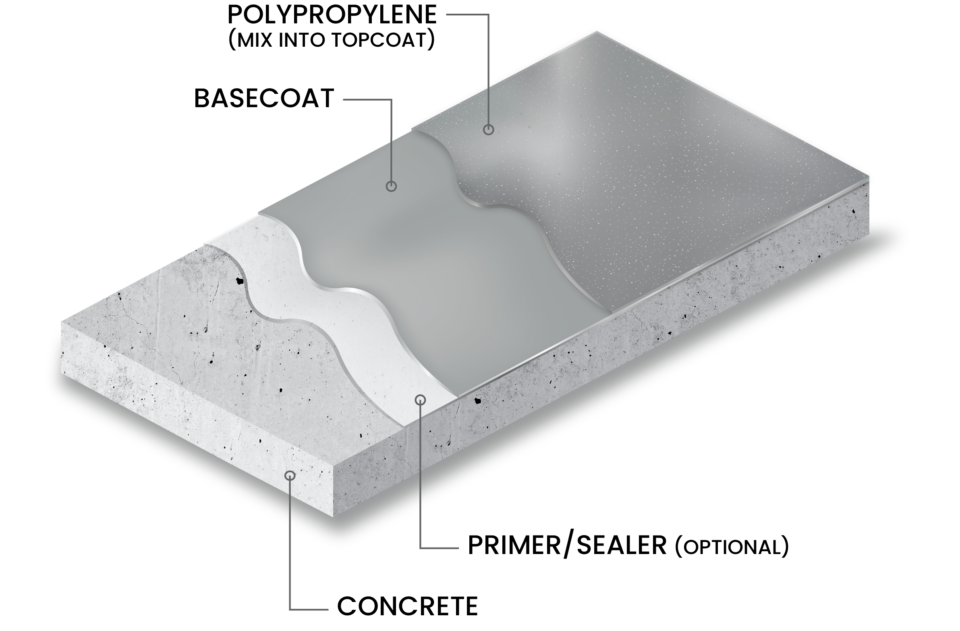

TEXTURE additives are used to enhance the surface of high-performance resinous floor coating systems. These functional fillers are available in three unique chemistries, including: POLYPROPYLENE, ALUMINUM OXIDE, and QUARTZ.

POLYPROPYLENE

This texture additive is a synthetic thermoplastic polymer material used in floor coatings to provide texture, reduce surface reflection, and lessen the risk of slip and fall injuries. POLYPROPYLENE is nearly invisible when suspended in a clear coating, making it perfect for enhancing the surface texture and maintaining the color or pattern of a flooring project.

Application

Based on total weight of coating, mix 3-10% POLYPROPYLENE or approximately 4-12 ounces per gallon. Mix well for proper dispersion. Apply coatings as recommended by manufacturer.

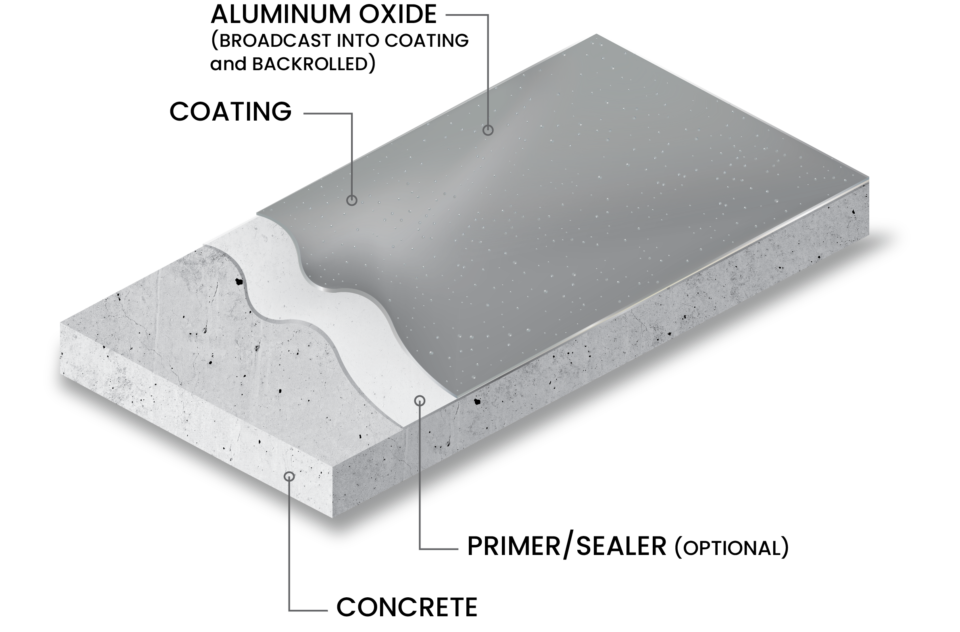

ALUMINUM OXIDE

This is a strong texture additive that can be used in harsh and industrial environments to create a durable anti-slip surface. ALUMINUM OXIDE is a dense white material that dries clear and can either be hand-broadcasted or mixed into a floor coating to enhance surface texture.

Application

Hand-broadcasting is recommended for the larger AO-50 (50 mesh) material and applied at a rate of 1 lb per 5-10 ft2. For the smaller AO-100 (100 mesh) and AO-200 (200 mesh) material, it is recommended to mix directly into the coating at a rate of 2-4 lb per gallon. Apply coatings as recommended by manufacturer.

*Consult your coatings manufacturer for specific recommendations.*

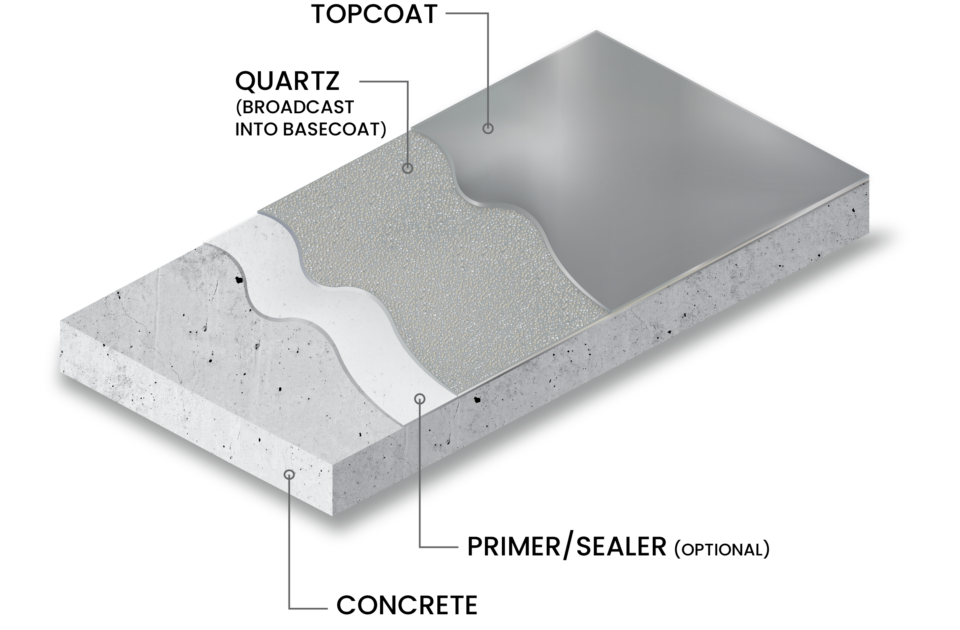

Clear-Coated Quartz

Quartz granules are hard and strong making them ideal for use as an aggressive anti-slip additive in industrial and heavy-duty environments. QUARTZ can be applied by hand-broadcasting or troweling the material into a clear or pigmented coating.

Application

Hand-broadcasting is recommended for the smaller Q1000-40S (40 mesh, spherical) material and applied at a rate of 1 LB per 1-5 SF2. For the larger Q1000-25A (25 mesh, angular) material, trowel application is recommended at a rate of 1 LB per 1-5 SF2. A pigmented topcoat is recommended to achieve optimal durability and aesthetics. Apply coatings as recommended by manufacturer.

*Consult your coatings manufacturer for specific recommendations.*

/_380x380_fit_center-center_none/PP_20.jpg?v=1686058971)

/_380x380_crop_center-center_none/PP_20.jpg?v=1686058971)

/_120x120_crop_center-center_none/PP_20.jpg?v=1686058971)

/_380x380_fit_center-center_none/PP_30.jpg?v=1686058970)

/_380x380_crop_center-center_none/PP_30.jpg?v=1686058970)

/_120x120_crop_center-center_none/PP_30.jpg?v=1686058971)

/_380x380_fit_center-center_none/PP_50.jpg?v=1686058970)

/_380x380_crop_center-center_none/PP_50.jpg?v=1686058970)

/_120x120_crop_center-center_none/PP_50.jpg?v=1686058970)

/_380x380_fit_center-center_none/PP_100.jpg?v=1686058971)

/_380x380_crop_center-center_none/PP_100.jpg?v=1686058971)

/_120x120_crop_center-center_none/PP_100.jpg?v=1686058971)

/_380x380_fit_center-center_none/AO_50.jpg?v=1686058971)

/_380x380_crop_center-center_none/AO_50.jpg?v=1686058971)

/_120x120_crop_center-center_none/AO_50.jpg?v=1686058971)

/_380x380_fit_center-center_none/AO_100.jpg?v=1686058972)

/_380x380_crop_center-center_none/AO_100.jpg?v=1686058972)

/_120x120_crop_center-center_none/AO_100.jpg?v=1686058972)

/_380x380_fit_center-center_none/AO_200.jpg?v=1686058971)

/_380x380_crop_center-center_none/AO_200.jpg?v=1686058972)

/_120x120_crop_center-center_none/AO_200.jpg?v=1686058972)