The Nitty-Gritty of Texture Additives

The non-porous surfaces of resinous floors are great for so many reasons: they protect the floor underneath from absorbing moisture, oil, or collecting dirt; are easy to clean; and are extremely durable. Though protecting the floor underneath and improving durability, the coatings on the floor may be very smooth or even slippery at times. Decorative products, like FLAKE or QUARTZ, can be used to create a light orange peel or gritty texture. But if you’re looking for something more, it may be time to consider a TEXTURE additive. TEXTURE additives enhance the final topcoat of resinous flooring and can be used to create anti-slip/anti-skid textures as well as knock down surface sheen for varying topcoat finishes.

A texture additive can improve anti-slip and anti-skid properties of your resinous floor, but which one is the right fit for your project? Let’s go over each of our TEXTURE products to help you decide which is right for you.

Polypropylene: Polypropylene is a common texture additive—it is not as aggressive as other texture additives and can be used in almost any environment. It is made of very fine polymer beads that are clear when mixed into topcoats. Generally, polypropylene is mixed into the final topcoat and rolled onto the surface. It is available in 4 mesh sizes ranging from large to small: 20, 30, 50, and 100.

Aluminum Oxide: This additive is harsher than polypropylene. It is a dense white material that dries clear in the final topcoat. Depending on the mesh size and load rate, it can also be used as a matting agent. However, due to its harsh texture, it is not recommended for all environments. It is best in demanding environments that require maximum grip or areas with greater slip and fall risk. The broadcast application method is recommended for the larger sizes like AO-50. For smaller sizes like AO-100 and 200, mix directly into the coatings.

Aluminum Oxide 325 mesh is exclusively a matting agent meant for use in creating semi-matte and matte topcoat finishes. While it adds an extremely fine grit to the surface texture, AO-325 should not be relied on for a strong anti-slip/anti-skid finish.

Clear-coated Quartz: Clear-coated Quartz is extremely durable and an aggressive texture additive. This product is best in industrial and heavy-duty environments with high traffic.

It is recommended for use in coatings underneath a colored topcoat or as a component in epoxy mortar systems as the natural quartz will be visible if used with a clear topcoat. Broadcast application is recommended for the 40-S grade material, while trowel application is recommended with the 25-A material.

The general mixing and application recommendations above are only suggestions based on product characteristics and testing. Depending on the thickness and percent solids of the coating being used, different mesh sizes may be required. Generally, the thinner the coating, the smaller the mesh size that can be used. If using a thicker coating, a larger mesh size is needed. Smaller size particles will sink in a thick topcoat and there will be no texture in the final floor. Application of these products can be very nuanced and depending on the other products used, can change case-by-case. It is always best to consult with your preferred coatings manufacturer for specific instructions.

For specific information and recommended load rates, visit our TEXTURE page.

Here are the tips for choosing the right basecoat color for your FLAKE project.

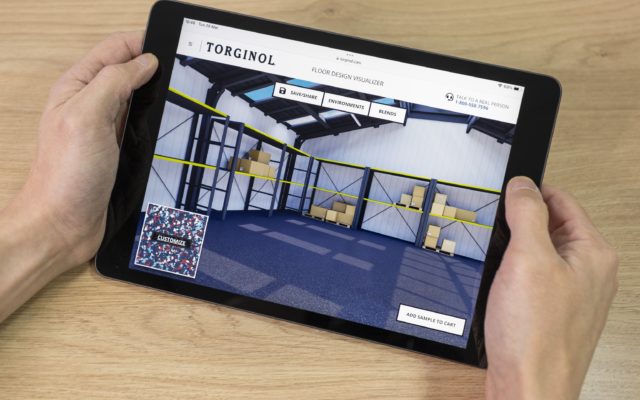

Learn more about the development of our new Floor Visualizer Tool!

Learn how to make your floors sparkle! No professional equipment required!